Course Search Results

Course Search Results

Course Name

Hot Axle Box Detector GE FUS FLMFCourse Description

Provides an understanding of Engineering specifications associated with specific types of hot axle box detector systems and how they work under normal operating conditions; also includes maintenance, faulting, repair and testing activity as well as procedures for maintaining personal safety.Audience

This course is designed to train persons required to undertake corrective maintenance of the GE FUS Hot Axle Box Detector system.Pre-requisiteBefore attending this training a person should have: Successfully completed Signal Engineering Maintenance 2, OR Other suitable similar or related training, & Attended a number of lineside equipment training courses & Not less than 2 years work experience in a signal maintenance / faulting / installation or testing environment.Duration:

5 Day(s)Class size:

6

Course Name

Hot Axle Box Detector GE FUS FLMFCourse Description

<p>Provides an understanding of Engineering specifications associated with specific types of hot axle box detector systems and how they work under normal operating conditions; also includes maintenance, faulting, repair and testing activity as well as procedures for maintaining personal safety.</p>Audience

This course is designed to train persons required to undertake corrective maintenance of the GE FUS Hot Axle Box Detector system.Pre-requisiteBefore attending this training a person should have: Successfully completed Signal Engineering Maintenance 2, OR Other suitable similar or related training, & Attended a number of lineside equipment training courses & Not less than 2 years work experience in a signal maintenance / faulting / installation or testing environment.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

Undertake corrective and preventative maintenance of Hot Axle Box Detector Systems. Undertake corrective and preventative maintenance of Hot Axle Box Detector Systems.GE FUSCompetence Awarded:

Sig 22; Sig 22.01Course Code:

STF 221Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits Undertake corrective and preventative maintenance of Track Circuits Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS Undertake corrective and preventative maintenance of Signalling Power Supplies Undertake corrective and preventative maintenance of Signalling Cables Take and relinquish responsibility for Signalling equipment Managing Site Safety Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activitiesPrerequisite Short Code:

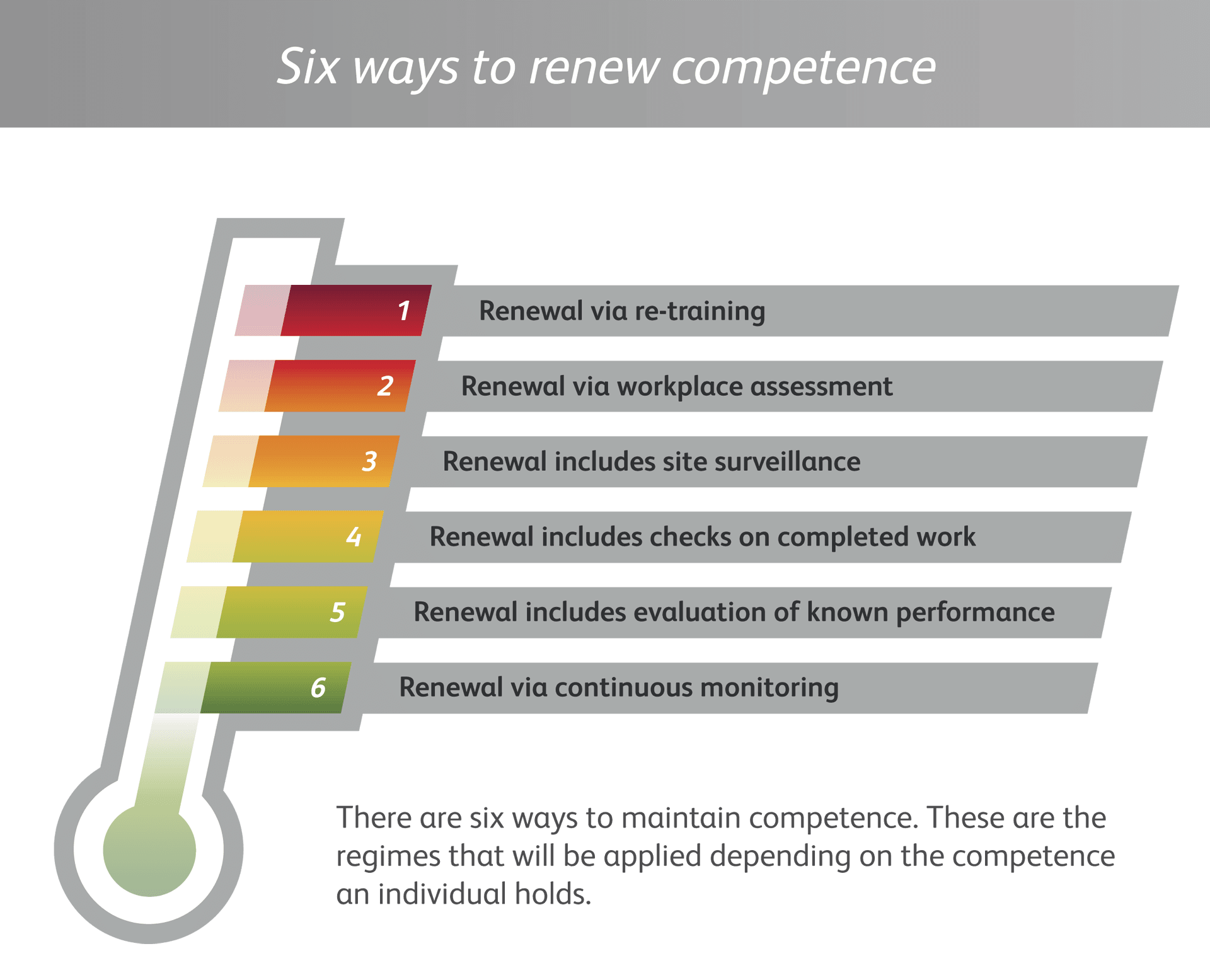

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 24; HSE T50 ; Sig 25Skills Assessment Scheme Regime:

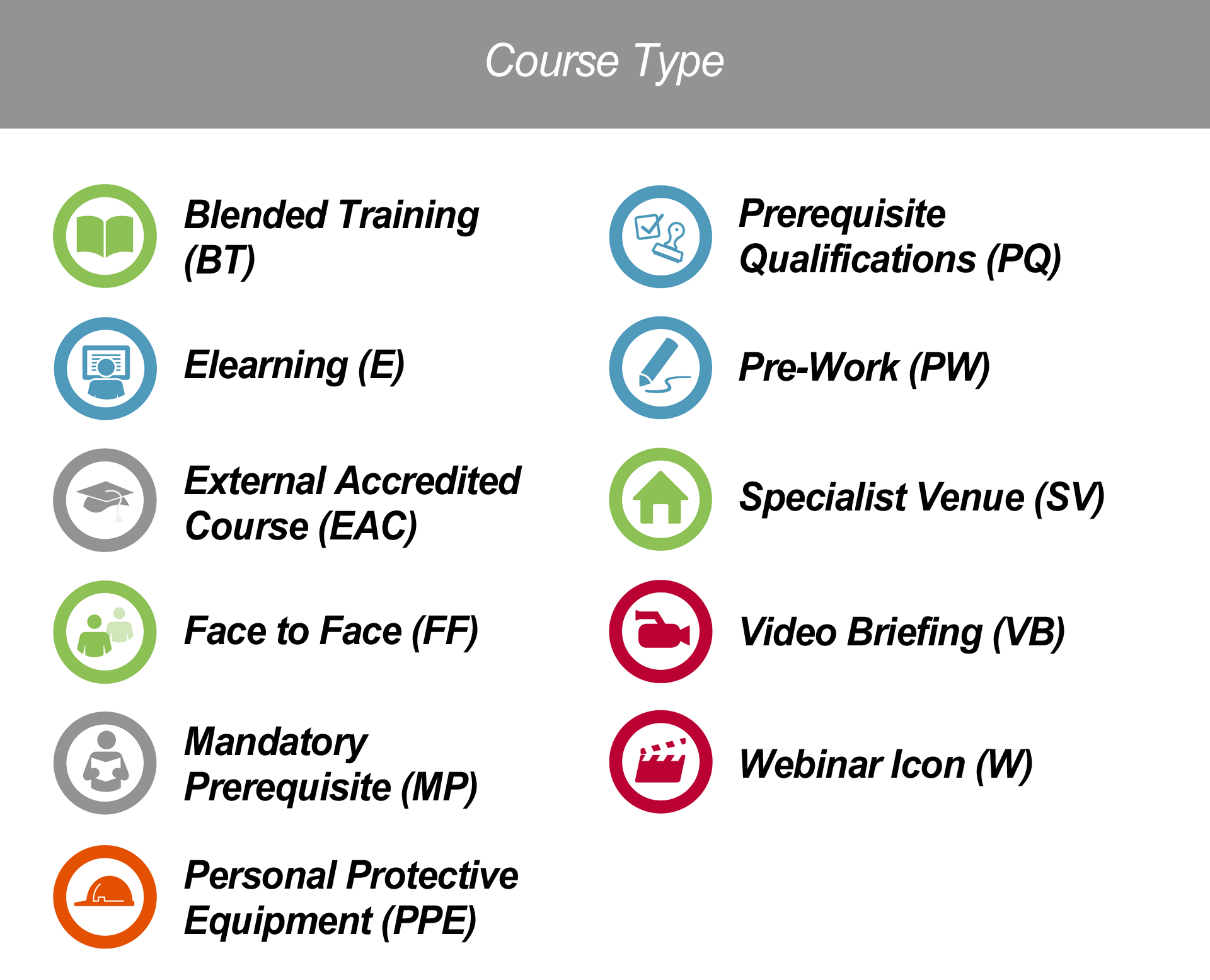

6Course Type:

Course Name

Hot Axle Box Detector GE FUS FLMFCourse Description

<p>Provides an understanding of Engineering specifications associated with specific types of hot axle box detector systems and how they work under normal operating conditions; also includes maintenance, faulting, repair and testing activity as well as procedures for maintaining personal safety.</p>Audience

This course is designed to train persons required to undertake corrective maintenance of the GE FUS Hot Axle Box Detector system.Pre-requisiteBefore attending this training a person should have: Successfully completed Signal Engineering Maintenance 2, OR Other suitable similar or related training, & Attended a number of lineside equipment training courses & Not less than 2 years work experience in a signal maintenance / faulting / installation or testing environment.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

Undertake corrective and preventative maintenance of Hot Axle Box Detector Systems. Undertake corrective and preventative maintenance of Hot Axle Box Detector Systems.GE FUSCompetence Awarded:

Sig 22; Sig 22.01Course Code:

STF 221Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits Undertake corrective and preventative maintenance of Track Circuits Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS Undertake corrective and preventative maintenance of Signalling Power Supplies Undertake corrective and preventative maintenance of Signalling Cables Take and relinquish responsibility for Signalling equipment Managing Site Safety Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activitiesPrerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 24; HSE T50 ; Sig 25Skills Assessment Scheme Regime:

6Course Type:

How to Book